Do these problems sound familiar?

- The oven seems to be fine one moment, and might even preheat for quite a while, before it suddenly shuts off.

- You can set the oven to heat, and it seems like it’s going to start, but nothing actually happens.

- The oven starts beeping randomly for no reason. You can get it stop for a while, but the beeping comes back eventually.

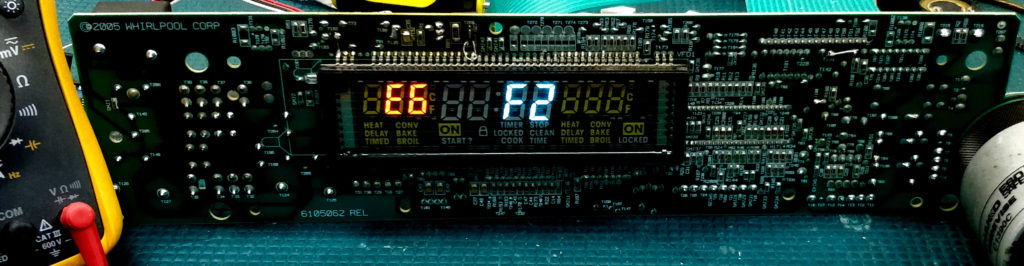

- ‘F1’ error code keeps popping up

These are the telltale symptoms of control board failure for many lines of GE equipment.

The control boards in these model series of GE/Kenmore ovens in particular are failing at a high rate:

The technical team at ApplianceBoardRepair is well acquainted with this problem and is well rehearsed in fixing it. Control board rebuilds are only $120.00 (plus inbound shipping), come with a one year warranty, and are turned around in 2-3 days at the ApplianceBoardRepair facility.

Search for your part on the site, select it for repair, fill out your information, and generate your shipping label all in less than five minutes!

Not sure if this is the service you need? Send us an inquiry and speak your mind. We are happy to listen and help. We’ll point you to the right place even if our service isn’t what you need.

This post caters to the following model and part numbers. Don’t see yours on the list? Contact us.

OEM PART NUMBER: WB27T10277

Aka:

WB27T10037, 911140, AP3426947, PS238575, EA238575, WB27K5272, AH238575, WB27K5321

BRANDS:

General Electric

MODELS:

JTP56BW1BB, ZET757BW1BB, ZET757BW2BB, JTP56WW2WW, ZET757WW2WW,

JTP56WW1WW, ZET757WW1WW, JT950SY1SS, JTP56AW2AA, JTP56AW1AA,

JTP56BW2BB

OEM PART NUMBER: WB27T10305

Aka:

PS238600, EA238600, AP3183198, AH238600, 911157

BRANDS:

General Electric

MODELS:

JTP27BD1BB, JTP15WA4WW, JTP27BA4BB, JTP15BD1BB, JTP27BA5BB,

JTP27WD1WW, JTP15WA5WW, JTP15WD1WW, JTP15BA4BB, JTP15CD1CC,

JTP27WA4WW, JTP15AD1AA, JTP27WA5WW, JTP15AA5AA, JTP15AA4AA,

JTP15BA5BB

OEM PART NUMBER: WB27T10211

Aka:

875257, EA238531, AH238531, AP2632964, PS238531

BRANDS:

General Electric

MODELS:

JTP18WA3WW, JT910WA3WW, JT910SA3SS, JTP18BA3BB, JT910BA3BB,

JT910AA3AA, JT910CA3CC, JTP18AA3AA

OEM PART NUMBER: WB27K5047

BRANDS:

General Electric

MODELS:

JKP44GP1, JKP45WP2WG, ZEK755WP2WG, ZEK754GP1, ZEK755WP1,

JKP45WP1, JKP44GP2BG, ZEK754GP2BG

OEM PART NUMBER: WB27K5154

BRANDS:

General Electric

MODELS:

ZEK736GP5BG, JKP17WT1WW, ZEK737WP5WG, JKP16GT1BB, ZEK737WP4WG,

JKP18AT1AA, ZEK736GP4BG

OEM PART NUMBER: WB27K5211

BRANDS:

General Electric

MODELS:

JKP54GT2BB, ZEK756GP7BG, ZEK757WP6WG, JKP56AT2AA, JKP55WV1WW,

JKP54GV1BB, JKP56AV1AA, JKP55WT2WW

OEM PART NUMBER: WB27K5040

BRANDS:

General Electric

MODELS:

JKP26GP1, JKP27WP2WG, JKP27WP1, JKP14WP2WG, JKP13GP2BG,

JKP26GP2BG, JKP14WP1, JKP13GP1

OEM PART NUMBER: WB27K5123

BRANDS:

General Electric

MODELS:

JKP14WP3WG, JKP26GP4BG, JKP26GP3BG, JKP13GP4BG, JKP13GP3BG,

JKP27WP3WG

OEM PART NUMBER: WB27K5190

BRANDS:

General Electric

MODELS:

JKP13GV1BB, JKP14WT1WW, JKP26GV1BB, JKP14WV1WW, JKP26GT1BB,

JKP27WV1WW, JKP15AV1AA, JKP13GT1BB, JKP27WT1WW

OEM PART NUMBER: WB27K5210

Aka:

AP2025174, WB27K5120, WB27K5121

BRANDS:

General Electric, Kenmore_Sears

MODELS:

JKP44GT1BB, JKP45WP3WG, ZEK755WP6WG, ZEK754GP5BG, 3634842594,

JKP45WV1WW, ZEK754GP3BG, ZEK754GP4BG, ZEK755WP4WG, ZEK754GP6BG,

JKP45WT1WW, JKP45WT2WW, ZEK755WP5WG, JKP44GV1BB, JKP44GP3BG,

ZEK755WP3WG, JKP44GT2BB, ZEK754GP7BG, JKP44GP4BG

OEM PART NUMBER: WB27T10264

Aka:

164D4171P012, AP3155966, PS238565, EA238565, 191D1576P012, WB27K5299, 844426, AH238565, 100-01069-09

BRANDS:

General Electric

MODELS:

JRP15WW1WW, JRP24BW3BB, JRP15WW2WW, JRP15BW2BB, JKP15WW1WW,

JKP27BW2BB, JKP27BW1BB, JKP15BW2BB, JKP15WW2WW, JKP15AW1AA,

JKP15BW1BB, JKP27WW2WW, JRP15BW1BB, JRP24BW2BB, JKP15AW2AA,

JRP15BW3BB, JRP15WW3WW, JKP27WW1WW, JRP24BW1BB

OEM PART NUMBER: WB27K5140

Aka:

WB27K5162, 100-639-28, WB27K5107, AP2025145

BRANDS:

General Electric, Kenmore_Sears

MODELS:

RF724GP5AD, JDP36GP5AD, JDP39WV1WW, JMP28GT1WH, RS734GP3WH,

RK737WS1WG, JMP28BW1AD, JMP28GT1AD, JMP31WW1WW, JRP15WT1WW,

JMP28BA2WH, JMP31WR2WH, JRP15WP3WG, JSP28GT1BB, JDP36GV1WH,

RF725GP5BG, JSP38GV1BB, JDP37GV1BB, JDP39WT1WW, JSP40AV1AA,

RS734GP3AD, JMP29GV1BB, JRP14GP3BG, JSP31GP4WH, RJ734GP3BG,

3634672994, JMP31WT1WW, JSP39WT1WW, JDP39WR5WH, JMP28GV1AD,

JSP38GS4BG, JDP36GP5WH, JDP37GT1BB, RF725GT1BG, JSP28GV1BB,

JSP26GV1WH, JRP24GT1BB, JSP39WV1WW, JRP24GP4BG, JSP39GS2WG,

JMP28GR2WH, JMP2SGR3WH, RK736GP5BG, JDP36GT1WH, JDP37GP5BG,

JSP26GT1WH, JSP38GT1BB, JMP29GR2BK, JSP40AS2AG, RF724GP5WH,

RS744GT1BG, JSP26GT1AD, JSP26GP4AD, JMP28GR3WH, JMP31WA1WW,

JDP36GT1AD, JMP31WA2WW, JMP28BA1AD, JDP36GV1AD, JRP24GV1BB,

JRP14GT1BB, JMP28BA1WH, JMP28BA2AD, JSP31WT1WW, JMP29GR3BK,

JSP38GS3BG, JMP28BW1WH, JMP28BW2AD, JMP28GV1WH, JMP29GT1BB,

JSP26GP4WH, JSP31WV1WW, JSP34AV1AA, JMP28BW2WH, JMP28GR3AD,

JRP14GP4BG, JRP14GV1BB, JRP15WV1WW, RK736GP4BG, JSP40AT1AA,

JMP31WV1WW, JSP26GV1AD, JRP24GP3BG, JMP28GR2AD

OEM PART NUMBER: WB27K5046

Aka:

WB27K5116, AP2025102, ap2025102

BRANDS:

General Electric

MODELS:

JKP16GP1BG, ZEK736GP2BG, ZEK737WP2WG, JKP16GP3BG, JKP17WP3WG,

ZEK736GP3BG, JKP16GP2BG, ZEK737WP3WG, JKP17WP2WG, JKP16GP4BG,

ZEK736GP1BG, ZEK737WP1WG, JKP17WPI, JKP18AS1AA, JKP16GPI,

JKP17WP1WG

OEM PART NUMBER: WB27K5048

Aka:

AP2025104, 346514, WB27K5119

BRANDS:

General Electric

MODELS:

JKP54GT1BB, JKP55WP1WG, ZEK756GP4BG, JKP55WP2WG, JKP54GP2BG,

JKP56AS1AA, JKP55WP3WG, ZEK757WP4WG, ZEK757WP5WG, ZEK757WP2WG,

ZEK756GP3BG, ZEK757WP3WG, ZEK756GP2BG, ZEK756GP5BG, JKP55WT1WW,

JKP54GP1BG, ZEK756GP6BG, JKP54GP4BG, JKP54GP3BG, ZEK757WP1WG,

JKP56AT1AA

OEM PART NUMBER: WB27K5203

Aka:

AP2025173, WB27K5197

BRANDS:

General Electric

MODELS:

JKP16GT2BB, JKP17WV1WW, JKP16GV1BB, JKP17WT2WW, JKP18AT2AA,

JKP18AV1AA, ZEK737WP6WG, ZEK736GP6BG

OEM PART NUMBER: WB27K10007

Aka:

PS238021, EA238021, ap2025074, AH238021, 769758, WB11K10015

BRANDS:

General Electric

MODELS:

JGBP86BEB3BB, JGBP90MEB4BC, JGBP90MEB2BC, JGBP90MEA2BC, JGBP86BEA1BB,

JGBP86BEB1BB, JGBP86BEA3BB, JGBP85BEB3BB, JGBP85BEB4BB, JGBP86CEB1CC,

JGBP85AEA1AA, JGBP85WEB1WW, JGBP85BEA3BB, JGBP85AEB1AA, JGBP90MEA3BC,

JGBP86CEB2CC, JGBP86WEA3WW, JGBP86AEB2AA, JGBP90MEB3BC, JGBP86AEA3AA,

JGBP90MEA1BC, JGBP86AEB1AA, JGBP86BEB2BB, JGBP86BEB4BB, JGBP86CEB3CC,

JGBP85WEB2WW, JGBP85CEB4CC, JGBP85CEB2CC, JGBP86WEB1WW, JGBP86WEB2WW,

JGBP86BEA2BB, JGBP86WEA2WW, JGBP86WEA1WW, JGBP85BEB1BB, JGBP85WEB3WW,

JGBP85BEB2BB, JGBP86WEB4WW, JGBP90MEB1BC, JGBP85BEA2BB, JGBP85AEA2AA,

JGBP85AEB4AA, JGBP85CEA1CC, JGBP85WEA2WW, JGBP86AEA1AA, JGBP86AEA2AA,

JGBP86CEB4CC, JGBP85AEB2AA, JGBP85WEB4WW, JGBP85WEA1WW, JGBP85CEB3CC,

JGBP85CEB1CC, JGBP86WEB3WW, JGBP85WEA3WW, JGBP86CEA1CC, JGBP85AEA3AA,

JGBP85AEB3AA, JGBP86AEB3AA, JGBP85BEA1BB

OEM PART NUMBER: WB12K19

Aka:

WB11K74, WB12K0019, 191D1001P020, AP2020547, WB11K0074

BRANDS:

General Electric

MODELS:

JGBP79WEV3WW, RGB750SEY1WW, JGBP79AEV2AA, JGBP79AEV1AA, JGBP79GEV1BB,

JGBP79GEV4BB, JGBP79GEV3BB, JGBP80MEV4BC, JGBP79WEV1WW, JGBP79WEV4WW,

JGBP79WEW1WW, JGBP79AEV3AA, JGBP79WEV2WW, JGBP79GEV2BB, JGBP80MEV2BC,

JGBP80MEV1BC, JGBP79AEW1AA, JGBP79BEW1BB, JGBP79AEV4AA

OEM PART NUMBER: WB12K7

Aka:

WB12K0007, EA231242, ap2622274, WB19X0270, WB27K5037, PS231242, WB19X270, 244900, AH231242

BRANDS:

Kenmore_Sears

MODELS:

3627191190, 3627191890

OEM PART NUMBER: WB27K5051

Aka:

ap2025107

BRANDS:

General Electric

MODELS:

JSP26GN2, RF724GP1, JDP37GL9, JSP38GN2, RS734GN2,

JSP28GN2, JSP31GN2, RF725GP1, RS744GN2, RF725GL9

OEM PART NUMBER: WB27K5045

Aka:

ap2025101

BRANDS:

General Electric

MODELS:

ZEK734GP2BG, ZEK734GP1, ZEK735WP2WG, ZEK735WP1

OEM PART NUMBER: WB27M13

Aka:

WB27M0013, EA238355, 254482, 346059, PS238355, AH238355, 345871, ap2632107, WB27K5052

BRANDS:

General Electric

MODELS:

JSP60GN3BG, JSP60GN1, JSP69WT1WW, JSP62GN2, JSP50GN3BG,

RS780GN1, JSP62GN3BG, JSP62GN1, JSP68GT1BB, JSP60GN2,

JSP50GN1, JSP50GN2

OEM PART NUMBER: WB27K5068

Aka:

ap2025120

BRANDS:

General Electric

MODELS:

RF724GP1, JCSP28GP2BG, JSP38GP1, RS744GP1, JCSP31GP2WH,

JCSP28GP1, JSP26GP1, RS734GP1, JDP36GP1, JSP28GP1,

JCSP31GP1, RF725GP1, JSP31GP1, JDP37GP1

OEM PART NUMBER: WB27T10327

Aka:

942797, PS238616, 191D1001P007, WB27K5056, WB27K5201, EA238616, AH238616, ap3156068, 100-673-00, 346103

BRANDS:

General Electric

MODELS:

JGRS14GEP2BG, RGJ534GEP2BG, RGJ534GEP1, JGRC14GEP1, JGRS14GEP1,

JGRS14GET2BB, JGRC14GEP2BG, JGRS14GET1BB, JGRS14GEV1BB

OEM PART NUMBER: WB27K5063

Aka:

347101, 345629, ap2632542

BRANDS:

General Electric

OEM PART NUMBER: WB27K5065

Aka:

ap2632544

BRANDS:

General Electric

OEM PART NUMBER: WB27K5137

Aka:

WB19X277, WB27X5509, WB27K5192, ap2632555, WB27K5158, WB27K5194, WB27K5074, WB27K5159, WB19X0277, WB27K5160, 100-639-48

BRANDS:

General Electric, Kenmore_Sears

MODELS:

3639584990, JB578GS1BG, 3639584690, RB767GN1, RB767GN2,

RB767GN3, RB767GN4WH, 3639584590, JB578GP1, JB579GR2WH,

JB579GR4WH, JB579GR3WH, JB579GR5WH, JB579GR1, JB578GS3BG,

JB578GP2, JBP79WS1, RB767GN5WH, RB768GN1, JB578GS2BG,

RB767GN5AD, RB767GN4AD, JBP56GS1

OEM PART NUMBER: WB27T10297

Aka:

AP3183444, 911154, EA238593, AH238593, PS238593

BRANDS:

General Electric

MODELS:

JTP56AA5AA, JT950SA5SS, JT950SA4SS, JTP56BA5BB, JTP56SD1SS,

JT950AA4AA, JT950CA4CC, JTP56AA4AA, JT950WA4WW, JTP56WA4WW,

JTP56BD1BB, JTP56CD1CC, JTP56WD1WW, JT950BA4BB, JTP56WA5WW,

JTP56BA4BB

OEM PART NUMBER: WB27T10219

Aka:

AP2633043, 875261, PS238538, EA238538, AH238538, WB27T10070, WB27T10069, WB27T10086, WB27T10073

BRANDS:

General Electric

MODELS:

JCT910SY1SS, JT910WA1WW, JCTP18BA2BB, JT910BA2BB, JTP18WA2WW,

JTP18BA2BB, JCTP18WA2WW, JTP18AA2AA, JCT910SA1SS, JT910AA2AA,

JT910WA2WW, ZET737BA2BB, JCTP18BA3BB, JCTP18WA3WW, JT910CA2CC,

JCT910SA2SS, JT910SA2SS, JTP18AA1AA, ZET737WA2WW, JT910SA1SS,

JCTP18WA1WW, ZET737WA1WW, JCT910SA3SS, JT910AA1AA, JTP18BA1BB,

JT910CA1CC, JT910BA1BB, JCTP18BA1BB, ZET737BA1BB, JTP18WA1WW

OEM PART NUMBER: WB27T10083

Aka:

AP2632694, WB12K0010, WB12K0012, WB12K5, WB12K12, 191D1001P005, WB12K10, WB12K0005

BRANDS:

General Electric, Kenmore_Sears

MODELS:

JGBP31GEP1, JGBP34GEP1, 36275970691, 3627351892, JGBP35GEP3,

3627586691, JGBP26GEN6, 3627381890, 3627585590, JGBP34GEV3WH,

RGB747GER2, 3627586692, 3627381191, JGBP26GEN7, JGBP34AEW1AD,

JGBP38GEV4BB, 3627586591, JGBP75BEY1BB, JGBP34GEV5WH, JGBP35AEV2AA,

JGBP35AEW1AA, 3627361892, 3627361992, 3627586992, JGBP34GEP3,

3627586590, JGBP35GEP2, JGBP35AEV4AA, RGB747GER1, 3627585990,

JGBP38GES1, JGBP26GEN4, JGBP34WEW1WH, JGBP35GEP6, 3627381990,

RGB747GER3, 3627361193, JGBP34AEV2AD, 3627361893, 3627351190,

JGBP38GEV1BB, 3627586990, 3627586991, JGBP35GEP5, 36275875691,

JGBP34WEV5WH, JGBP35GEV3BB, JGBP35GEV1BB, 3627351192, JGBP35WEV1WW,

JGBP31GEP3, JGBP34GEP2, 3627381190, JGBP26GEN3, JGBP34GEV1AD,

JGBP61WEW1WW, JGBP34AEV1AD, 36275970690, 3627586592, JGBP38GES2,

JGBP38GEV2BB, 3627361191, JGBP35WEV2WW, JGBP34GEV5AD, JGBP61WEV1WW,

JGBP35AEV1AA, JGBP35GEV2BB, JGBP34GEV1WH, JGBP35GEP4, JGBP35WEW1WW,

JGBP34AEV3AD, JGBP34GEV2AD, JGBP35GEP1, JGBP35GEV4BB, JGBP34GEV4AD,

JGBP34GEV3AD, JGBP34WEV3WH, RGB746GEN1, JGBP34GEP4, JGBP79WEV3WW,

3627351891, RGB747GEP1, 3627361993, JGBP35BEW1BB, 3627351890,

JGBP34WEV4WH, 3627351191, JGBP26GEN2, 3627351592, JGBP35WEV4WW,

36275875690, 3627381891, JGBP34WEV2WH, 3627585690, JGBP34GEV2WH,

JGBP35AEV3AA, JGBP38GEV3BB, 3627361891, 36275879691, 3637351591,

JGBP34GEP5, JGBP26GEN5, JGBP34AEV5AD, 3627381991, JGBP35WEV3WW,

3627361192, JGBP34GEV4WH, JGBP34WEV1WH, 36275876691, 36275879690,

JGBP75AEY1AA, JGBP61WEW2WW, 3627361890, JGBP31GEP2, 3627585591,

JGBP75WEY1WW, 36275876690, JGBP34AEV4AD, 3627351590, 3627586690,

3627361190, 3627361991

OEM PART NUMBER: WB27T10272

Aka:

EA238571, 911138, WB27T10065, WB27T10273, AP3155968, WB27T10066, AH238571, PS238571

BRANDS:

General Electric

MODELS:

JTP15WA2WW, JTP27BA3BB, JTP15AA2AA, JTP15AA3AA, JTP15BA1BB,

JTP15BA3BB, JTP27WA1WW, JTP15WA3WW, JTP27BA2BB, JTP15AA1AA,

JTP27BA1BB, JTP15BA2BB, JTP15WA1WW, JTP27WA2WW, JTP27WA3WW

OEM PART NUMBER: WB27T10312

Aka:

EA238604, AP3186178, 911161, PS238604, AH238604

BRANDS:

General Electric

MODELS:

JT910SA4SS, JTP18BA5BB, ZET737WA4WW, ZET737BA5BB, JTP18WD1WW,

JTP18AA4AA, JTP18SXD1SS, JTP18CD1CC, JTP18SD1SS, JT910CA5CC,

ZET737BA4BB, ZET737BD1BB, JT910WA4WW, JTP18BD1BB, JTP18WXD1WW,

JT910CA4CC, ZET737WA5WW, JT910AA5AA, JTP18BA4BB, JT910AA4AA,

JT910WA5WW, ZET737WD1WW, JT910BA4BB, JTP18BXD1BB, JTP18WA4WW,

JT910BA5BB, JTP18AA5AA, JTP18WA5WW

OEM PART NUMBER: WB27T10336

Aka:

EA238623, 911174, AP3188670, PS238623, AH238623

BRANDS:

General Electric

MODELS:

JCKP15BD1BB, JCKP15WD1WW

OEM PART NUMBER: WB27T10287

Aka:

WB27T10059, AH238584, 875280, AP3155970, WB27T10057, EA238584, PS238584, WB27T10058, WB27T10140

BRANDS:

General Electric

MODELS:

JT950SA2SS, JT950WA1WW, JT950SA1SS, ZET757WA2WW, ZET757WA3WW,

JT950SA3SS, JT950AA2AA, JTP56WA1WW, JTP56BA1BB, ZET757WA1WW,

JTP56AA3AA, JTP56BA2BB, JT950BA1BB, JTP56AA1AA, ZET757BA1BB,

JT950CA2CC, JTP56AA2AA, ZET757BA2BB, JT950CA3CC, JTP56WA3WW,

JTP56WA2WW, JT950AA3AA, JT950CA1CC, JT950BA3BB, JT950WA3WW,

JT950WA2WW, JT950AA1AA, ZET757BA3BB, JT950BA2BB, JTP56BA3BB

OEM PART NUMBER: WB27T10265

Aka:

832673, AH238566, EA238566, WB27K5273, AP3141629, PS238566

BRANDS:

General Electric

MODELS:

JTP15BW3BB, JTP27BW3BB, JTP27WW1WW, JTP15BW2BB, JTP27BW2BB,

JTP15WW2WW, JTP27WW3WW, JTP15WW3WW, JTP15WW1WW, JTP15BW1BB,

JTP27BW1BB, JTP27WW2WW

OEM PART NUMBER: WB27T10270

Aka:

WB27T10271, AH238570, PS238570, AP3155967, EA238570, 875278

BRANDS:

General Electric

MODELS:

JKP15WA3WW, JRP15WW5WW, JRP24BD1BB, JKP27WA3WW, JKP27BA3BB,

JRP24BW5BB, JKP15BA3BB, JRP15BW5BB, JKP15AA3AA

OEM PART NUMBER: WB27T10350

Aka:

AP3186914, EA238634, AH238634, PS238634, 942802

BRANDS:

General Electric

MODELS:

JGBP79MEF1BC, JGBP79WEB5WW, JGBP35DED4BB, JGBP35BEA8BB, JGBP35DED2WW,

JGBP35DED3BB, JGBP79CEB4CC, JGBP79BEB4BB, JGBP79CEB7CC, JGBP35CEA4CC,

JGBP35DED4WW, JGBP79CEB6CC, JGBP79MEF2BC, JGBP79BEB7BB, JGBP35DED2BB,

JGBP79MEF3BC, JGBP35DED3WW, JGBP35DED3CC, JGBP35BEA9BB, JGBP35WEA7WW,

JGBP35DED4CC, JGBP79MEB3BC, JGBP79WEB4WW, JGBP79BEB5BB, JGBP79MEB2BC,

JGBP79WEB7WW, JGBP35CEA3CC, JGBP79CEB5CC, JGBP35WEA9WW, JGBP35CEA5CC,

JGBP35DED2CC, JGBP79BEB6BB, JGBP35BEA7BB, JGBP35WEA8WW, JGBP79WEB6WW

OEM PART NUMBER: WB27T10276

Aka:

AH238574, WB27T10064, WB27T10142, 898246, WB27T10063, WB27K5298, WB27T10067, WB27T10141, EA238574, AP3189149, PS238574

BRANDS:

General Electric

MODELS:

JCKS05BA2BB, JKP27BA2BB, JCKP15WA2WW, JKP15AA2AA, JKP27WA1WW,

JRS04BW1BB, JKS05BA2BB, JKS05BA1BB, JRS04BW2BB, JCKS05BA1BB,

JCKP15WA1WW, JKP15BA2BB, JKP15WA1WW, JCKP15BA1BB, JKP15AA1AA,

JRS04BW4BB, JCKS05WA2WW, JKP27BA1BB, JKP27WA2WW, JCKP15BA3BB,

JKP15BA1BB, JRS04BW3BB, JKP15WA2WW, JKS05BW1BB, JCKP15BA2BB,

JKS05BW2BB

OEM PART NUMBER: WB27T10348

Aka:

AP3191459, EA238632, PS238632, AH238632, 911182

BRANDS:

General Electric

MODELS:

JKP15BD1BB, JKP15AD1AA, JKP15WD1WW, JKP27WD1WW, JKP27BD1BB,

JKP15CD1CC

OEM PART NUMBER: WB27K5172

BRANDS:

General Electric

MODELS:

JTP18AT1AA, ZET737WV1WW, JTP18AT2AA, JTP16GV1BB, JTP18AV1AA,

JTP16GV2BB, JTP16GT1BB, ZET736GV1BB, JTP18AV2AA, JTP17WV2WW,

JTP17WT1WW, JTP17WV1WW

OEM PART NUMBER: WB27K5212

BRANDS:

General Electric

MODELS:

JCTP16GV1BB, JCTP17WV3WW, JCTP17WV1WW, JCTP16GV3BB

OEM PART NUMBER: WB27K5213

BRANDS:

General Electric

MODELS:

JTP44GV1BB, JTP44GV2BB, JTP45WV1WW, JTP56AV1AA, ZET756GV1BB,

ZET757WV1WW, JTP56AV2AA, JTP45WV2WW, JTP55WV2WW, JTP55WV1WW,

JTP54GV2BB, JTP54GV1BB

OEM PART NUMBER: WB27T10207

Aka:

PS238527, 911123, 191D1578P003, WB27K5336, AH238527, AP3155965, EA238527, WB27T10035, WB27K5302, 100-00794-00B

BRANDS:

General Electric

MODELS:

JTP18WW1WW, ZET737BW2BB, JTP18BW1BB, JTP18WW2WW, ZET737WW2WW,

JT910SY1SS, JTP18AW2AA, JTP18BW2BB, ZET737WW1WW, JCTP17BW1BB,

JTP18AW1AA, JCTP17WW2WW, JCTP17WW1WW, ZET737BW1BB

OEM PART NUMBER: WB27T10308

Aka:

PS238601, AH238601, 911158, EA238601, AP3184711

BRANDS:

General Electric

MODELS:

JTP17SC3SS, JTP15SD1SS, JTP17SC2SS

OEM PART NUMBER: WB27T10311

Aka:

AH238603, 911160, PS238603, EA238603, AP3186915

BRANDS:

General Electric

MODELS:

JCTP18WA5WW, JCTP18WD1WW, JCTP18BD1BB, JCT910SA4SS, JCTP18BA5BB,

JCTP18SD1SS, JCTP18WA4WW, JCTP18BA4BB

OEM PART NUMBER: WB27K10008CT

Aka:

AP5954424, ap5954424, WB27K10008

BRANDS:

General Electric

MODELS:

JGBP79CEB2CC, JGBP35GRA1WW, JGBP35GZA2WW, JGBP35DED1CC, JGBP35GZA1WW,

JGBP35WEA5WW, JGBP79CEB1CC, JGBP35GXA3WW, JGBP79BEB2BB, JGBP79AEA3AA,

JGBP35GXA5WW, JGBP79WEB1WW, JGBP35WEA6WW, JGBP35AEA3AA, JGBP79AEA2AA,

JGBP79BEA1BB, JGBP79CEA1CC, JGBP79AEB1AA, JGBP79CEB3CC, JGBP35BEA1BB,

JGBP35BEA3BB, JGBP35AEA1AA, JGBP35DED1BB, JGBP79BEA4BB, JGBP35GZA3WW,

JGBP35AEA5AA, JGBP79AEA1AA, JGBP79AEB3AA, JGBP79WEB3WW, JGBP35GXA2WW,

JGBP35WEA2WW, JGBP35AEA4AA, JGBP35BEA4BB, JGBP35GRA3WW, JGBP79WEA1WW,

JGBP35CEA2CC, JGBP79BEA3BB, JGBP79AEA4AA, JGBP35BEA2BB, JGBP35CEA1CC,

JGBP35WEA4WW, JGBP79WEA2WW, JGBP35WEA1WW, JGBP79BEB1BB, JGBP79WEA3WW,

JGBP79AEB2AA, JGBP35BEA5BB, JGBP35WEA3WW, JGBP35BEA6BB, JGBP79BEB3BB,

JGBP79MEB1BC, JGBP79WEB2WW, JGBP35AEA6AA, JGBP35GXA1WW, JGBP79BEA2BB,

JGBP79WEA4WW, JGBP35GRA2WW, JGBP35DED1WW, JGBP35AEA2AA